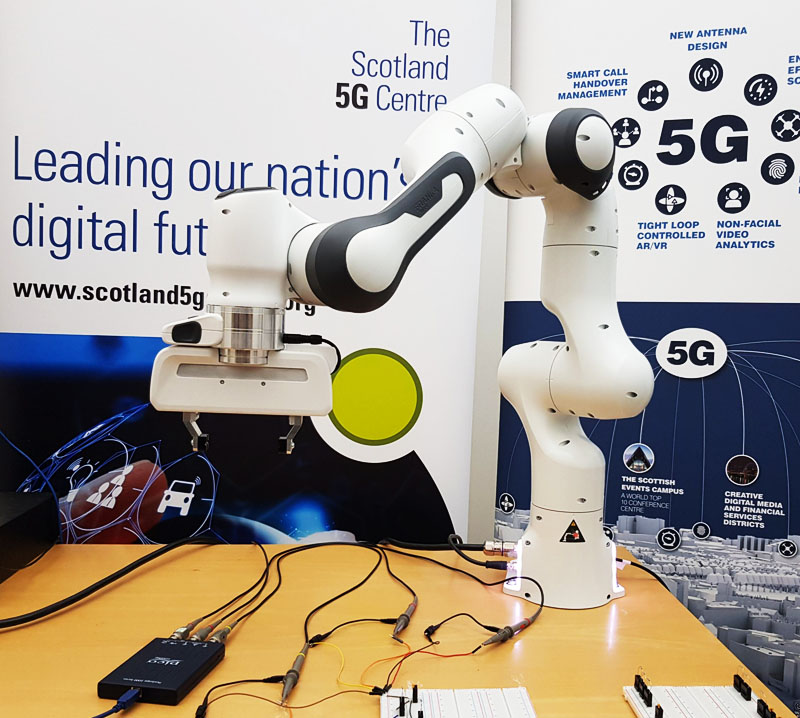

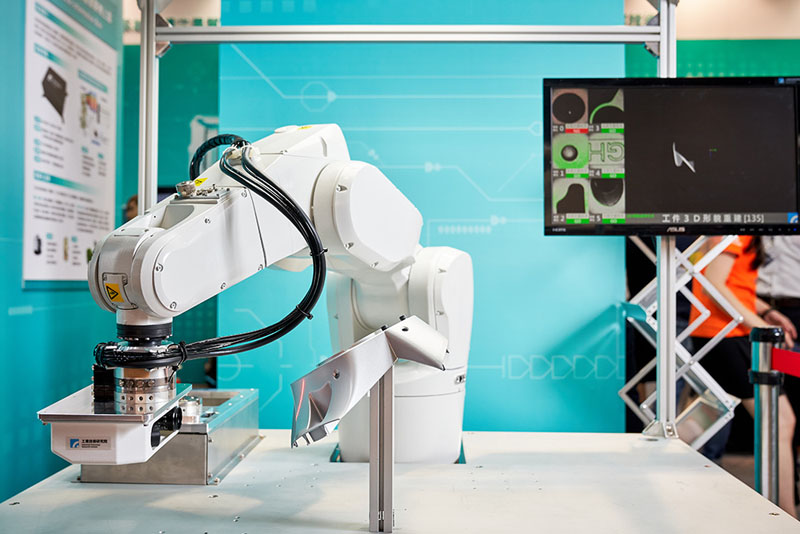

Robotic Laser Welding

Robotic Laser Welding

Robotic laser welding offers several advantages over traditional welding methods. Firstly, it provides a higher level of precision and accuracy, resulting in better weld quality and consistency. Secondly, it allows for faster welding speeds, leading to increased productivity and efficiency. Additionally, robotic laser welding is a non-contact process, reducing the risk of damage to the workpiece and minimizing the need for post-welding cleanup. Moreover, it offers greater flexibility in terms of weld joint geometry and material compatibility. Overall, robotic laser welding offers improved weld quality, increased productivity, and greater flexibility, making it a preferred choice in many industrial applications.

Robotic laser welding, powered by Daihen welding machine and controlled by B&R Acopostrak, is revolutionizing the robotic process automation industry. This advanced technology combines the precision of laser welding with the efficiency of robotic automation, resulting in faster and more accurate welding processes. With the ability to perform complex welds on various materials, robotic laser welding is transforming industries such as automotive, aerospace, and electronics. The integration of Daihen welding machine and B&R Acopostrak ensures seamless communication and control, maximizing productivity and minimizing errors. This innovative solution is driving the future of automation, making manufacturing processes more efficient and cost-effective.