Robotic Welding In Manufacturing

Robotic Welding In Manufacturing

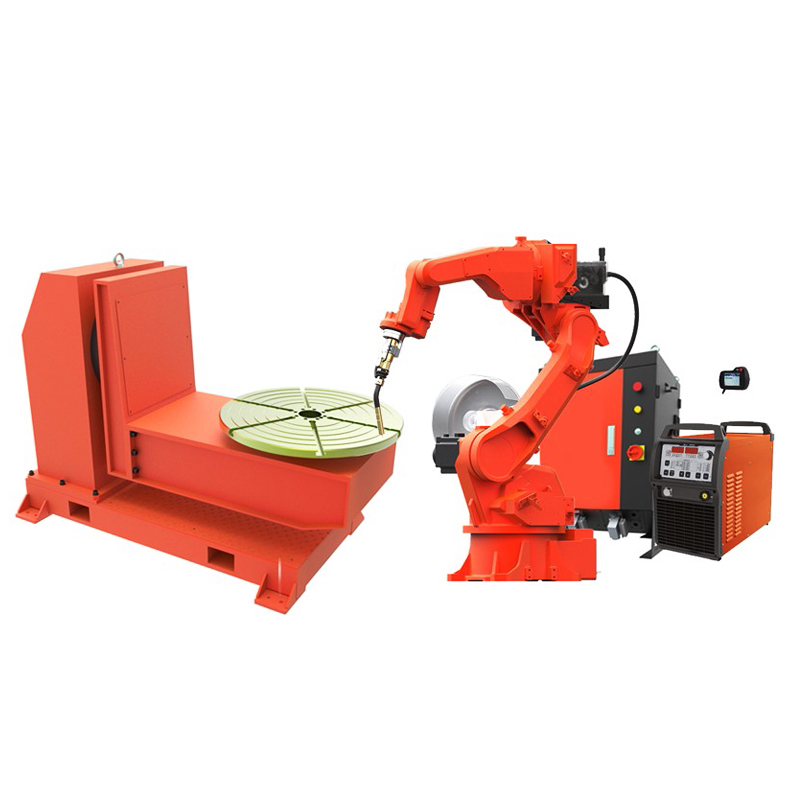

Robotic welding in manufacturing offers several advantages. Firstly, it improves productivity by increasing the speed and efficiency of the welding process. Robots can work continuously without getting tired or requiring breaks, leading to higher production rates. Secondly, robotic welding ensures consistency and precision in weld quality. The robots can follow programmed instructions accurately, resulting in fewer defects and improved product quality. Additionally, robotic welding enhances worker safety by reducing the need for human operators to be in close proximity to the welding process. This minimizes the risk of accidents and injuries. Overall, robotic welding offers increased productivity, improved quality, and enhanced safety in manufacturing.

Robotic Welding In Manufacturing

Robotic welding is widely used in manufacturing for its efficiency and precision. It is commonly used in industries such as automotive, aerospace, and electronics. Robotic welding systems can perform repetitive welding tasks with high accuracy and speed, resulting in improved productivity and reduced labor costs. These systems are capable of welding various materials, including steel, aluminum, and stainless steel. They can also handle complex welding patterns and produce consistent weld quality. Additionally, robotic welding offers a safer working environment as it eliminates the need for human operators to be exposed to hazardous welding fumes and sparks. Overall, robotic welding has become an essential tool in modern manufacturing processes.