OCTG Pipe Threading Machine

Main advanced Features

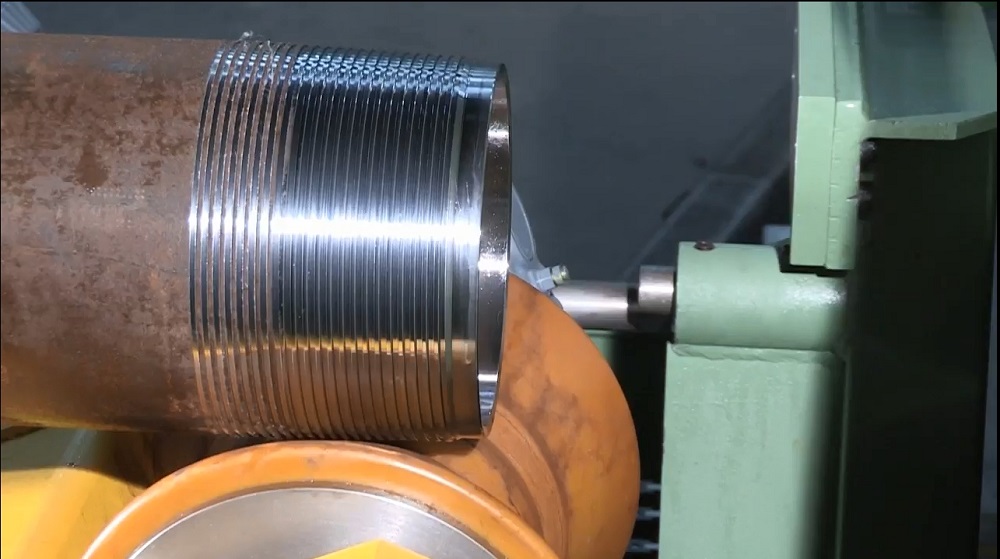

1. Good rigidity: The tube threader Configurates 45 OC Cast Iron Slant Bed, Big Through Hole, and rigidity Spindle Bearings

2. High Processing accuracy: Advanced engineering, experienced machine building employees, and Powerful control systems all guarantee the pipe threader with high accuracy.

3. High reliability, high accuracy, easy maintenance

4. Intelligent Control and intuitive interface, easy operation

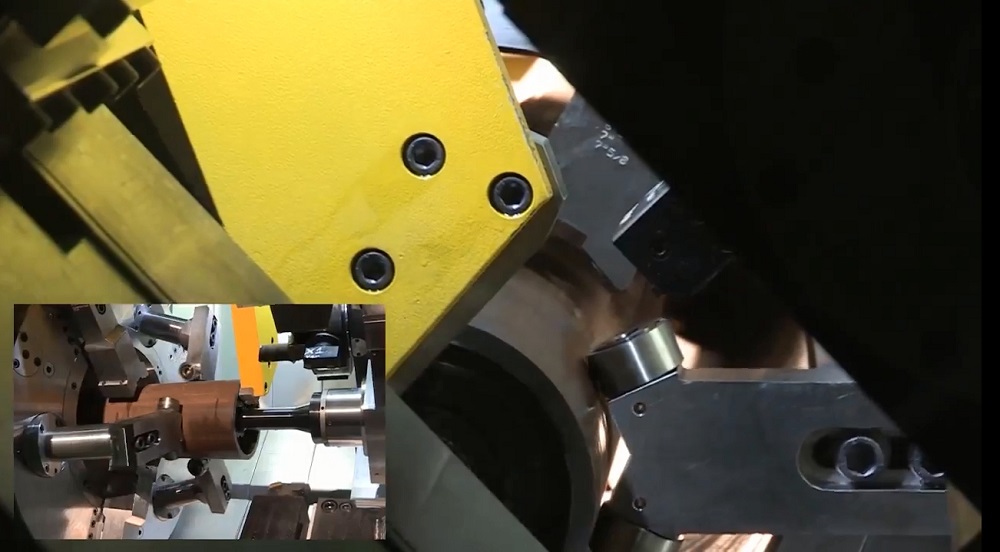

5. 5-Axis, three Hydraulic Turret, Total 7 Position Design enhance the processing efficiency

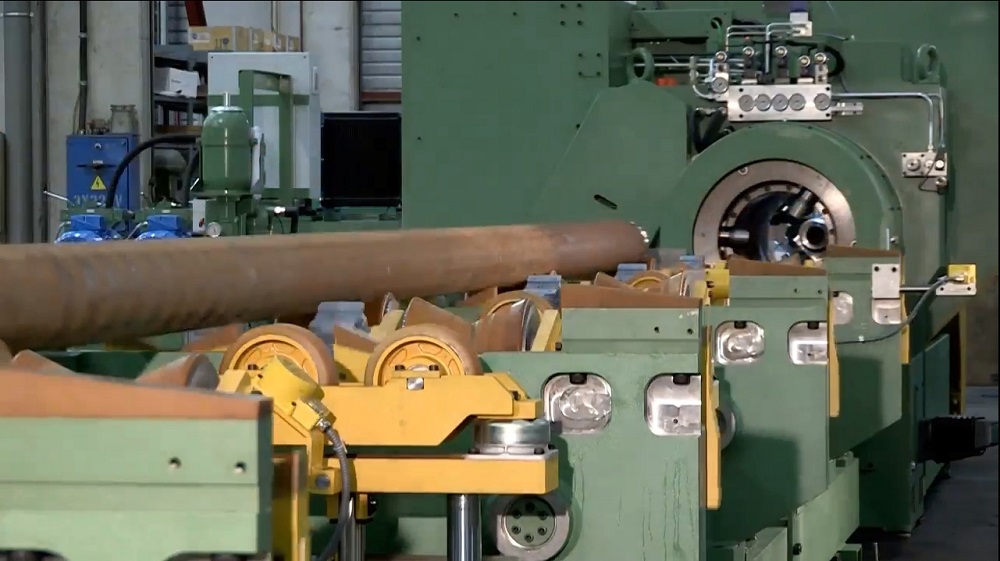

The Pipe finishing machine also called the Pipe threading machine, pipe threader, Pipe threading lathe, or pipe threader, is a machine we designed for API and Premium Connection Production, widely used in the oil industry for casing pipe and coupling threads production with unmatched advantage by conventional lathe., we are the second tube threading machine, coupling threading machine manufacture just after PMC Colinet, also can say we are the Chinese PMC Collinet. but we do the tube threader more chipper with similar quality and better service.

Pipe Threading Machine Constructure

1.The main parts of the tube threader are cast with high-performance cast iron, and secondary aging treatment which guarantees stable performance and good accuracy retention.

2. The main shaft adopts the big through-hole structure, the bearing adopts the high-precision tapered roller, and the hydraulic oil cooling lubrication makes the whole shafting have the characteristics of good rigidity, low-temperature rise, and high precision

3. The bed adopts 45 inclination Angle, and the internal steel plate adopts a cylindrical structure, which greatly improves the turning property, accuracy, and accuracy retention

4. The guide rail adopts steel box rail, quenching treatment, the friction surface of the guide rail adopts a resin-coated process, the movement friction resistance is small, the rigidity and shock absorption is good, and the life is long.

5. The carriage Slides are hydraulically balanced to balance the weight of the Slide and further improve the dynamic characteristics of the threading machine

6. The threading machine is equipped with a fully enclosed protection house that can effectively prevent the splash of coolant

7. The Threading machine adopts Siemens or Fanuc Control System and can achieve the automatic Processing

Pipe Threading Machine Specification

| Item | Unit | JMT-7 | JMT-13 | JMT-20 |

| Pipe Dia | mm | 48.26-177.8 | 139.7-339 | 219-508 |

| Through Hole Dia | mm | 195 | 370 | 640 |

| Spindle Speed | Rpm | 1000 | 700 | 400 |

| Spindle Power | kw | 93 | 93 | 93 |

| X/Z Axis Travel | mm | 110/600 | 160/600 | 400/600 |

| X/Z Axis Speed | m/min | 10/10 | 10/10 | 10/10 |

| Chucks | Double Hydraulic Chucks | |||

| Control System | Siemens or Fanuc by Customer Choice | |||