Coupling Finishing Machine

Main advanced Features

1. Product Rotating Technology

2. Excellent Quality and Accuracy

3. Tooling Designed to Optimize Machine Productivity

4. Exclusively Desheng Index Chuck

5. 4-Position Hydraulic Turret

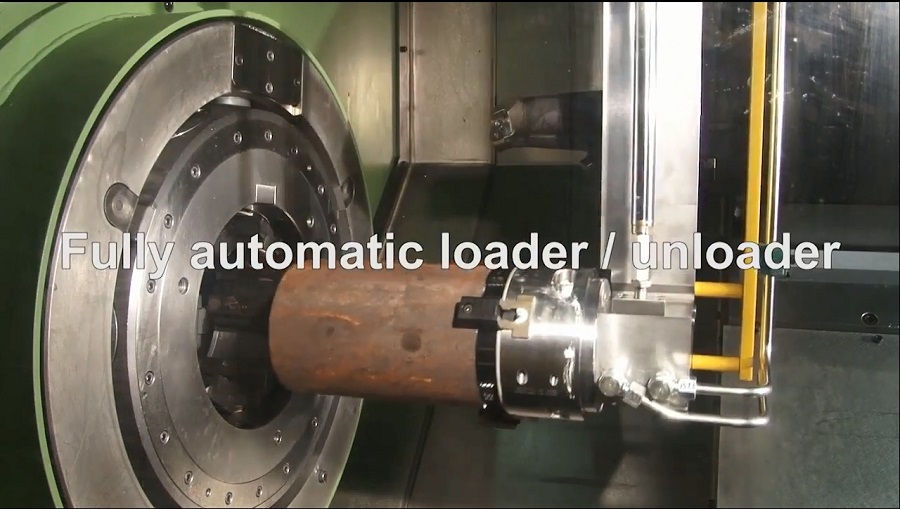

6. Gantry Structure automatic loading and unloading System

7. Highly integrated with a Robotic system can make all lines fully automated

8. Swivel Chucks, one-time clamping , the whole processing finish

JMC Series Couple Threading Machine

The Coupling Threading Machine, also known as the Coupling Finishing Machine, Coupling Threader, or Coupling Threading Lathe, is specifically designed for API and Premium Connection Production.

It is extensively utilized in the oil industry to produce coupling threads with unparalleled advantages over conventional lathes. We proudly hold the position of being the second largest manufacturer of Tube Threading Machines and Coupling Threading Machines, following PMC Colinet

We can confidently claim that we are China's equivalent to PMC Collinet; however, our tube threaders offer a more cost-effective solution without compromising on quality or service.

JMC Series Coupling Threading Machine Specification

| Item | Unit | JMC-7 | JMC-13 | JMC-20 |

| Pipe Dia | mm | 60.325-177.8 | 127-339 | 177.8-508 |

| Through Hole Dia | mm | 150 | 195 | 640 |

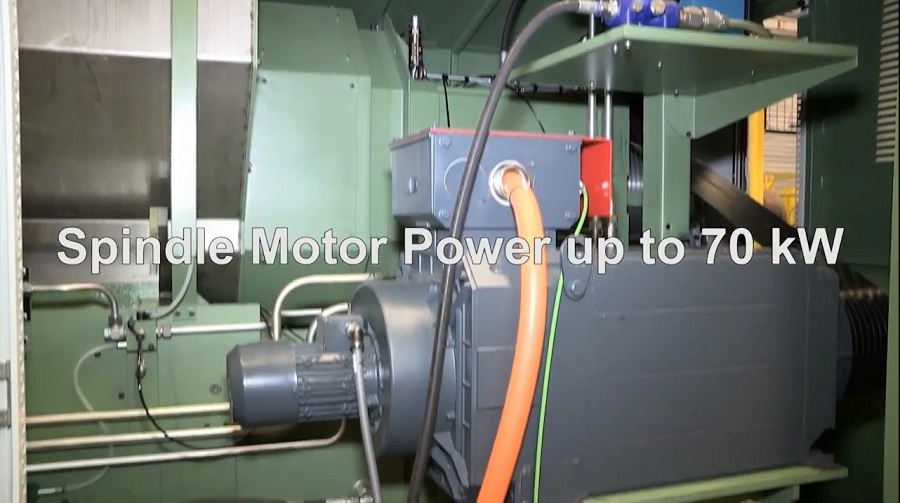

| Spindle Speed | Rpm | 1100 | 700 | 400 |

| Spindle Power | Kw | 75 | 75 | 93 |

| X/Z Axis Travel | mm | 450 / 450 | 600 / 600 | 600/600 |

| X/Z Axis Speed | m/min | 10 /10 | ||

| Turret | 4 Position Hydraulic Turret | |||

| Chucks | Double Hydraulic Swivel Chucks | |||

| Control System | Siemens Or FANUC by Custer's Choice | |||

Coupling Threading Machine Constructure

The main parts of the Coupling Threader are cast with high-performance cast iron, and secondary aging treatment which guarantees stable performance and good accuracy retention.

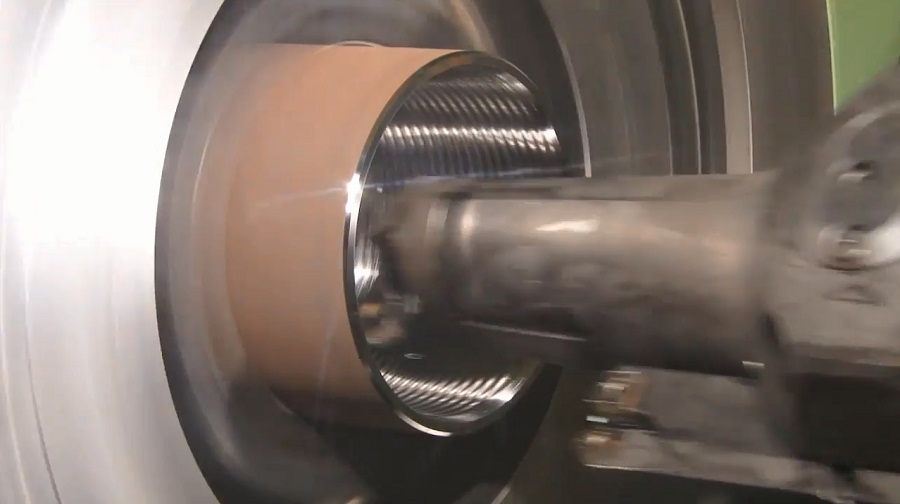

2. The main shaft adopts the big through-hole structure, the bearing adopts the high-precision tapered roller, and the hydraulic oil cooling lubrication makes the whole shafting have the characteristics of good rigidity, low-temperature rise, and high precision

3. The bed adopts 45 inclination Angle, and the internal steel plate adopts a cylindrical structure, which greatly improves the turning property, accuracy, and accuracy retention

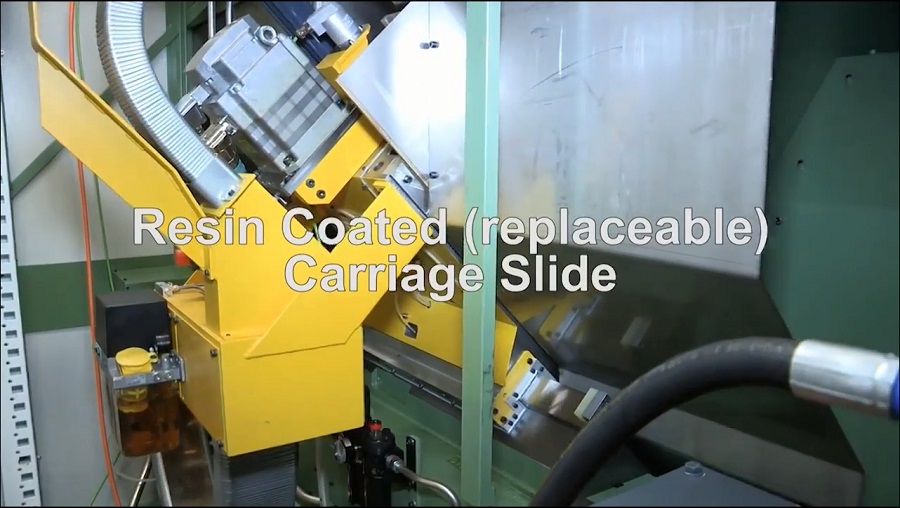

4. The guide rail adopts steel box rail, quenching treatment, the friction surface of the guide rail adopts a resin-coated process, the movement friction resistance is small, the rigidity and shock absorption are good, and the life is long.

5. The carriage Slides are hydraulically balanced to balance the weight of the Slide and further improve the dynamic characteristics of the threading machine

6. The threading machine is equipped with a fully enclosed protection house that can effectively prevent the splash of coolant

7. The Threading machine adopts Siemens or Fanuc Control System and can achieve the automatic Processing

The Coupling Threading Machine Main Parts

1. The coupling threading machine working system

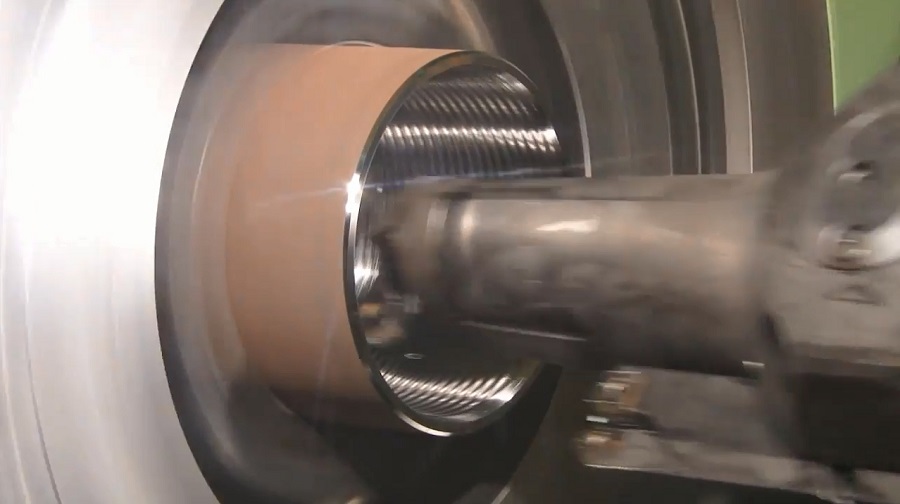

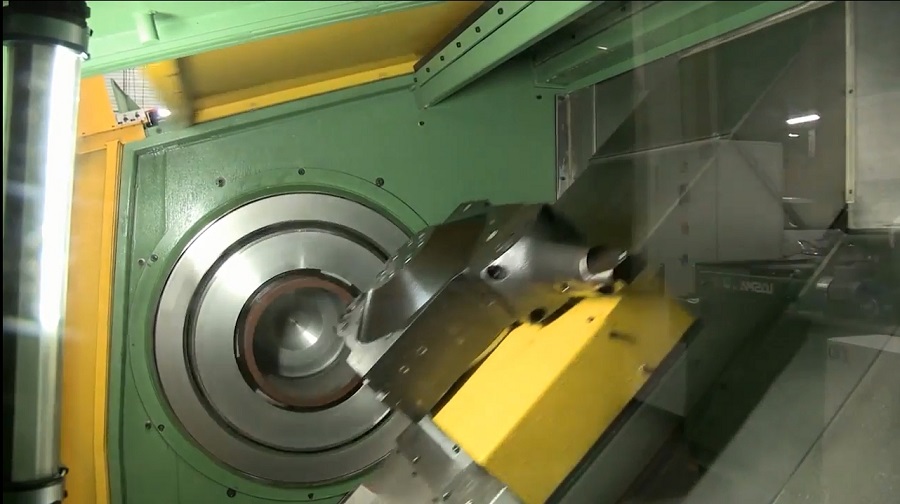

2. Cnc Coupling Threading Machine Index Swivel Chuck

3. The Coupling Threading Mahine Turret System

4. The Coupling Threading Machine Main Spindle Motor System

5. The Coupling Threading machine Resin Coated Carrage Slide

6. The Coupling Machine Chips Convey System

7. Coupling Threading Machine fully automatic Loader and Unloader

All the Machines we can tailed by our engineer team according to customers requirements , from concept to the

real job .